Wireless Remote Monitoring for Rail Cars

The Challenge

There are nearly 1.5 million railroad cars in the United States alone, and railroad companies would prefer to know the location and current status of every single one of them. Are the hatches open or closed? Are the handbrakes on or off? Are wheel bearings overheating and calling for preventative maintenance? Are the internal temperatures appropriate for the on-board cargo?

Just a few decades ago, railroads could only answer these questions by having train crews and yard clerks physically inspect the trains. So it’s no surprise that railroads have been eager to adopt helpful technologies when they became available. Tracking car locations became easier with arrival of automatic equipment identification (AEI) systems, which use wayside scanners to read transponders mounted on passing rail cars. Preventative maintenance was improved with the additional of wayside scanners that measure wheel temperatures and broadcast alerts when a high heat conditions are detected.

But one railroad wanted more. They wanted to be able to track as many parameters as possible, and to be able to access all of the data in real time, at a single location

The Solution

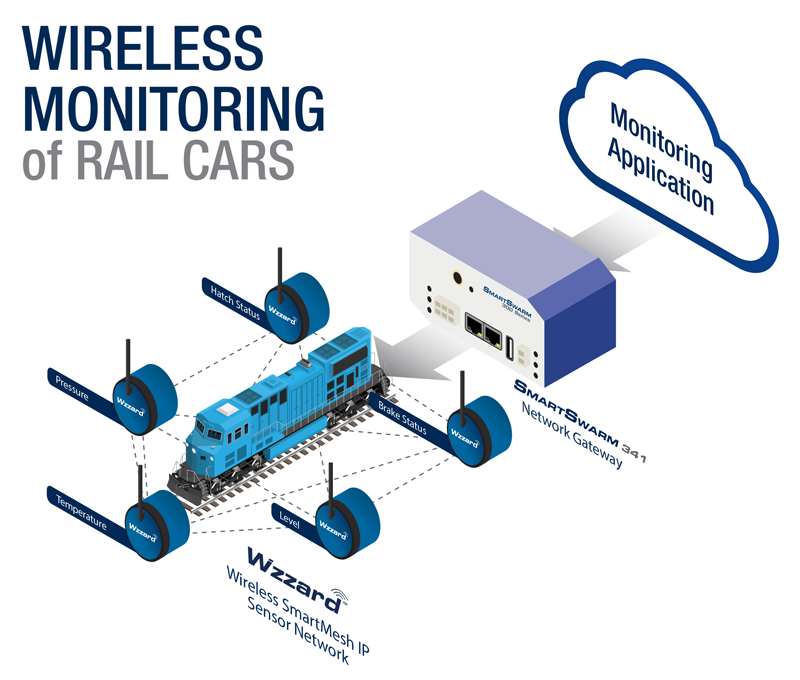

A remote asset monitoring service provider addressed the problem using the B+B SmartWorx Wzzard Sensor platform. They connected the sensors in the rail cars to wireless, battery-powered Wzzard Intelligent Edge Nodes. Wzzard Intelligent Edge Nodes form a self-healing mesh network that reports the sensor data to the Wzzard Network Gateway, which provides Ethernet connectivity via either cellular or wired connections. The service provider also equipped each rail car with a GPS tracker. Like the edge nodes, the GPS device reported to the network gateway. And thanks to the cellular networks, all of this real time data could now be monitored at the central control office.

Recommended Posts

Predictive Maintenance When Utilizing a Compressed Air System

November 12, 2018

Environmental Monitoring for Transportation Main Networking Hubs

November 7, 2018