A Smart Sensing Solution for a Commercial Creamery

The Challenge

Modern creameries produce a multitude of different ice cream flavors, with all kind of ingredients. Keeping everything at exactly the right temperature and the correct humidity is the key to protecting flavor and controlling bacterial growth. A creamery uses a lot of refrigeration, and that means that the operators will not only have to monitor the temperature and ambient humidity in many different parts of the plant; they’ll have to monitor the refrigeration systems for ammonia leaks and do preventative maintenance before small problems become catastrophic.

We were contacted by a creamery whose operations still relied upon standalone sensors that had to be read by human technicians. The call was triggered when the refrigeration in a cold storage unit failed on a Sunday, when the plant shuts down for cleaning. A huge quantity of product was lost, simply because no one was monitoring the thermometers. The creamery needed a better system.

The Solution

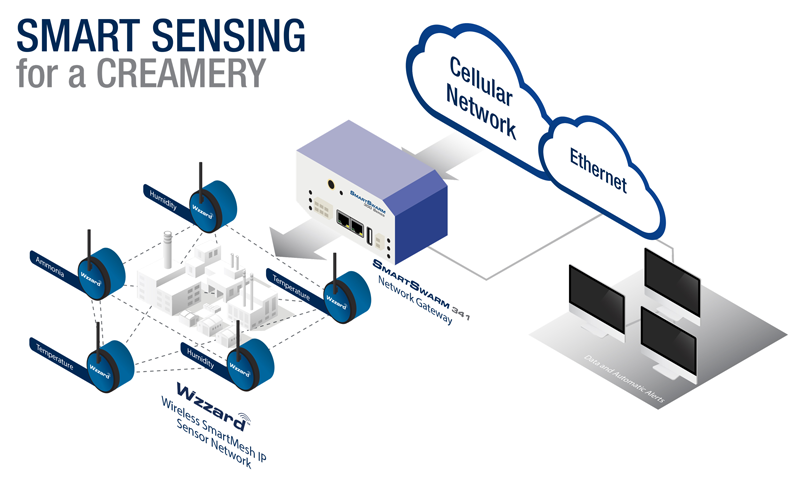

B+B SmartWorx solved the problem with the Wzzard Sensor Platform. We connected the plant’s existing sensors to wireless, battery-powered Wzzard Intelligent Edge Nodes. The Intelligent Edge Nodes form a self-healing mesh network that reports the sensor data to the Wzzard Network Gateway, which provides Ethernet connectivity via either cellular or wired connections. In locations where wired connections are available, the gateway can use them as the primary and provide automatic fail-over to cellular if the connection is broken.

The Intelligent Edge Nodes are configured to report on exception. If readings on the attached sensors exceed set parameters, the nodes will report that to the network gateway. And the next time the temperature starts to go haywire in one of the creamery’s cold storage units, the appropriate plant managers will receive notifications on their cell phones.

Recommended Posts

Predictive Maintenance When Utilizing a Compressed Air System

November 12, 2018

Environmental Monitoring for Transportation Main Networking Hubs

November 7, 2018