Energy & Environment > Distributed Energy Resources Management

Driving Energy Intelligence Through Distributed Energy Resources Management

Quick Guide to

Advantech DERM

Optimising the Performance and Value of the Distributed Energy Resources Management (DERM)

Renewable energy at a glace

With the ever increasing demand for energy, the enormous grid connections needed in operating renewable energy management have become a key component to improving energy efficiency and digitalisation is a critical facilitator in ensuring that effective energy transformation achieves a sustainable future.

-

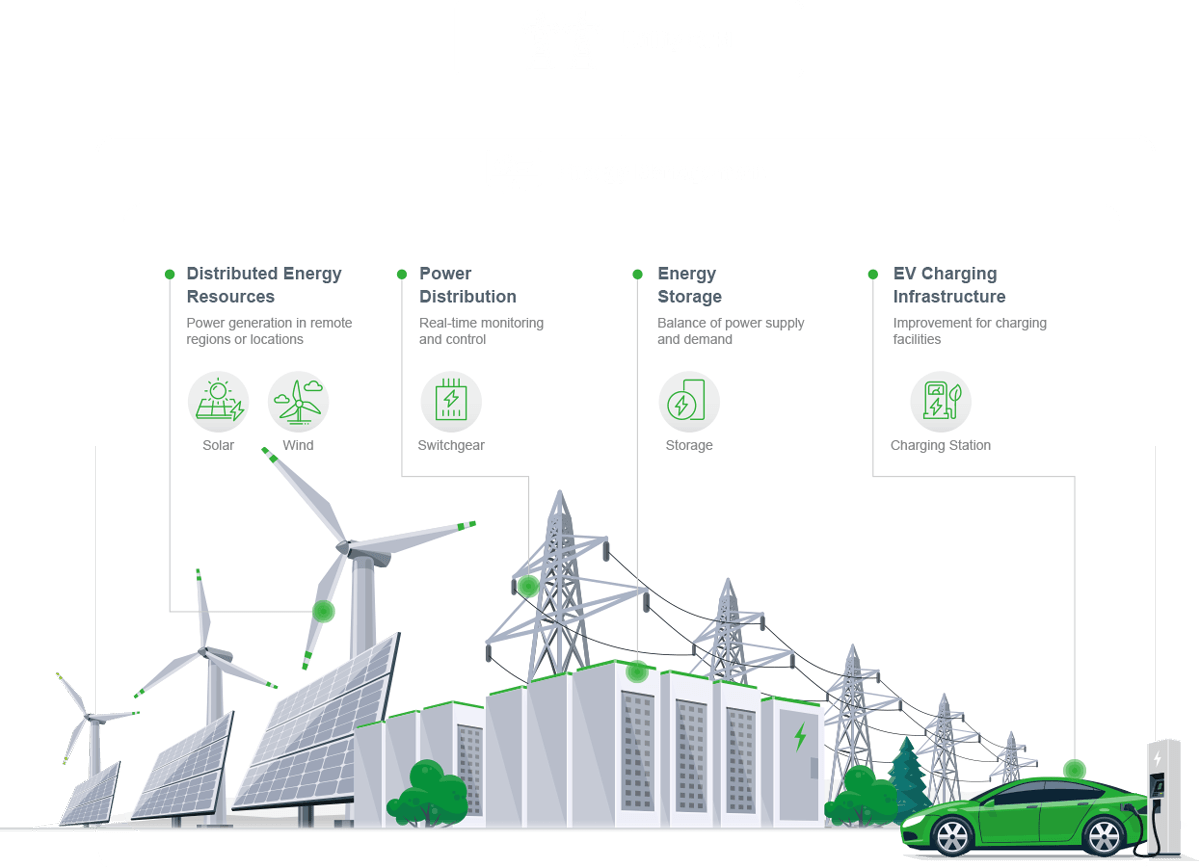

Distributed Generation

ButtonIntegration and management of renewable energy resources

DERM is the most efficient solution that seamlessly generates solar energy and other distributed energy resources and integrates them

into the grid

-

Power Distribution Center

ButtonProven performance and reliability in harsh environments

Ensures the quality of power supply and improves the safety of critical operating equipment to guarantee cost-optimised operations and maintenance management

-

Energy Storage

ButtonReliable power supply for efficient demand management

Makes the most of your renewables by balancing and coordinating solar or battery storage, ultimately improving electricity supply reliability

-

Electric Vehicle Charging Station

ButtonOptimised charging service and energy efficiency

As the market for EV is growing, this infrastructure requires a complete solution from data collection, to wireless communication and data visualisation for smart mobility and greener driving

Distributed Energy Resources System

Optimised facility management and performance across the entire distributed energy resources infrastructure

Meet the Challenges of Future Energy Requirements

Integrating the energy mix from centralised power plants and renewables into new models of energy distribution

-

Different geographical locations

ButtonRenewable energy sources come from many sources and can be dispersed in different geographical locations. The task is how to integrate distributed

generation of electricity from different sources into a single clean and reliable power supply.

-

Grid stability and reliability

ButtonMinimising transmission line and productivity loss while deploying distributed energy resources (DER) is crucial to maximising grid resilience to utilise more sustainable energy resources.

-

Load balancing in power systems

ButtonThere are many consumption variables that can lead to undesirable unbalanced distribution. Therefore, a balanced loading of the electrical grid is critical to reduce technical losses and improve the efficiency of energy resources.

Our Ability to Master the Challenges

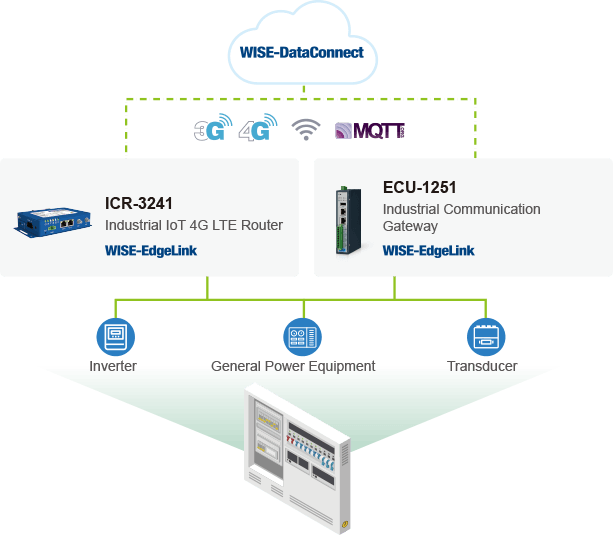

Distributed Solar Power Generation

Distributed generation technologies are ideal for generating power in different geographical locations. Advantech DERM solution with IIoT technologies minimises the amount of energy lost in generation, long-distance transmission, and distribution.

Explore the distributed generation solution for lower cost, stronger grids, and clean electricity.

Featured products

Power Distribution Center

Intelligent control is the only way to manage the entire lifecycle of switchgear and reduce manual detection errors during the flow of power. Robust connection technology ensures reliable power distribution, balanced loading, and network communication.

Learn more

about our solution designed to enhance energy efficiency and safety.

Featured products

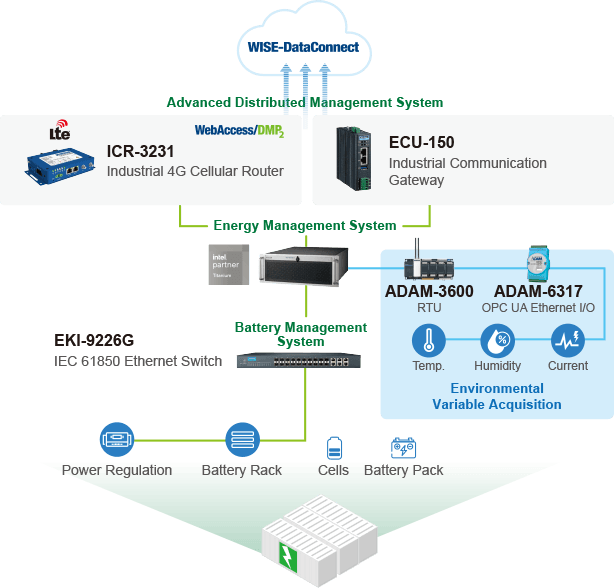

Energy Storage

Battery storage rack systems play an important role in

integrating and accelerating renewable energy deployment. Advantech's solution allows you to take full advantage of on-site generated energy.

Contact us to make the most of your renewable

energy generation for optimised storage asset

management.

Featured products

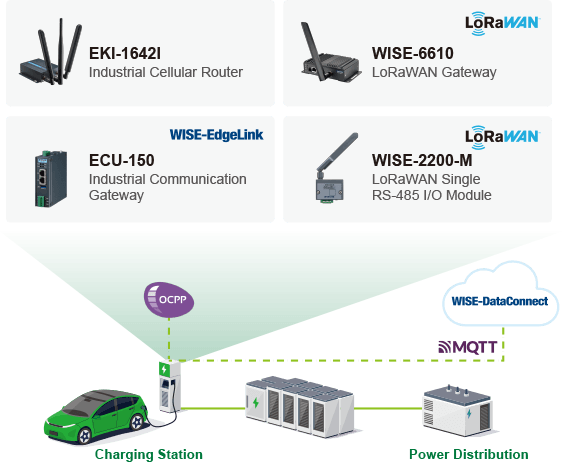

EV Charging Station

5G and AI technology ensure all the necessary grid connections to manage charging facilities in real time. Advantech DERM solution provides reliable hardware and connects it to the cloud, which helps you to bring energy-efficient charging to life while improving the service and optimising the energy cost.

Click and join us to meet the needs of the next generation of smart mobility.

Featured products

-

Photo By: John DoeEKI-1642I

Edge Connectivity & Gateway Solution

Smart Device Solution

Success Stories

Value-adding DERM solutions our customers need

-

City skyline

View MoreSmart Monitoring Solutions for Solar Panels

-

Birthday Sparks

View MoreMirai Electronics and Advantech Work Hand-in-hand to Achieve a Sustainable Future for Singapore

-

Fashion Magazine

View MoreRelay of network transmission technologies brings wind-farms nearer to management

-

Blurred Lines

View MoreAdvantech and Sunforce Collaborate on a Smart Monitoring System for Taiwan's First Micro-biomass Power Plant

-

View More

Advantech's Comprehensive Range of Solutions Prove Crucial in Developing Experimental Solar Glass Design for Dubai Airport

-

View More

Electric Grid Modernisation Challenges: The Importance of Implementing Edge Intelligence for Active Grid Management

Advantech Newsletter

Sign up for the latest industrial I/O and automation product and event updates, industry news, case studies, and more from Advantech.

Follow Advantech

How Can We Help?