A Flexible Solution for Flexible Work Cells

The Challenge

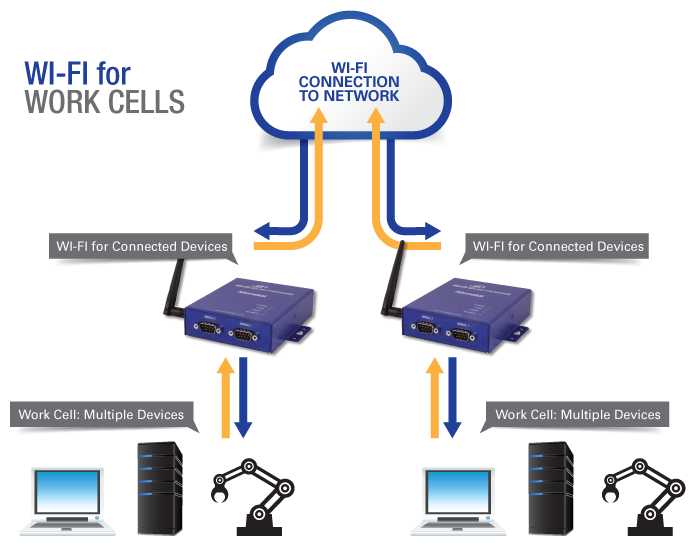

Traditional manufacturing uses assembly lines to break processes down into individual steps. Machinery is permanently positioned to maximize efficiency and throughput. But that model lacks the flexibility needed for the production of custom work and small lot sizes. One alternative is the work cell, where the machinery and devices required for a specific project can be temporarily grouped together until a custom job is finished.

A precision mechanics company specializing in turning, boring and milling custom pieces with special profiles and tolerances decided that stringing Ethernet cable to their flexible work cells caused too many problems. The cables were too vulnerable to mishaps, and any time the work cells were reconfigured, the cabling had to be reconfigured as well. The manufacturer needed an easy-to-use wireless solution that was robust enough for industrial environments.

The Solution

One of B+B value added resellers provided the manufacturer with B+B’s wireless router and Wi-Fi access point, the Airborne APXG-Q5420. The Airborne APXG-Q5420 provides both Ethernet and serial interfaces and gives connected equipment Wi-Fi access to the network, wherever the work cell may happen to be. The APXG-Q5420 supports robust security protocols for industrial grade Wi-Fi security.

Recommended Posts

Predictive Maintenance When Utilizing a Compressed Air System

November 12, 2018

Environmental Monitoring for Transportation Main Networking Hubs

November 7, 2018